SILVER BRAZING RODS

AG 301

Cu-Ph brazing filler rod with silver content

TECHNICAL DATA

Brazing temperature: 732-816ºC

Electrical conductivity: 5 Sm/mm2

TYPICAL APPLICATIONS

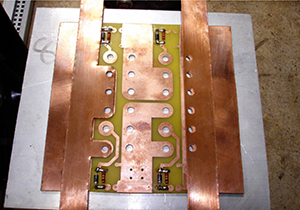

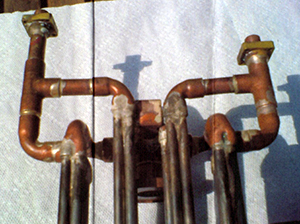

Capillary brazing and braze welding of copper, gun metal, Cu Zn, Cu Sn alloys in the construction of apparatus, electric motors and pipework. In precision mechanical workshops, for installation work and heating systems, in breweries, dairies and shop fittings. For water pipes (cold and hot water) in copper, beer piping, bus bars and squirrel cage rotors.

AG 301 SPL

Cu-Ph alloy containing high silver content

TECHNICAL DATA

UTS: 22-27 kgf/mm2

Brazing temperature: 704-816ºC

Elongation: 5%

TYPICAL APPLICATIONS

For brazing of copper tubes, apparatus, refrigeration pipes, air conditioning pipes, motor windings.

AG 302

Cu-Ph brazing filler rod with high silver content

TECHNICAL DATA

UTSL 25-28 kgf/mm2

Brazing temperature: 704-816ºC

Elongation (L=5d): > 10%

Electrical conductivity: 7 Sm/mm2

TYPICAL APPLICATIONS

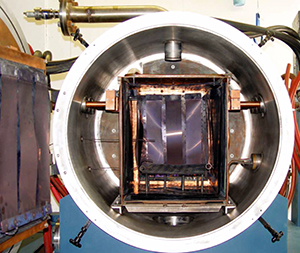

Capillary brazing of copper- copper joints which are subjected to severe loading, electric motors and pipework construction; on heat exchanger; in refrigeration engineering for joints operating at very low temperatures; on pipework subjected to vibrations and severe alternating thermal stress. Brazing of Cu-Zn and Cu- Sn alloys, gun metal, etc. Unsuitable for use in sulphurous environments, as well as on Fe and Ni alloys.

AG 306

Silver brazing filler rod with high silver content which bonds at low temperature

TECHNICAL DATA

UTS: 35-40 kgf/mm2

Brazing temperature: 595-630ºC

Elongation: 25%

TYPICAL APPLICATIONS

Capillary brazing on steels, stainless steels, malleable cast iron, copper, copper alloys, nickel, nickel alloys & hard metals; also for joints between the metals named above. Apparatus construction, precision machine parts, shipbuilding, precision tools, joints on copper conductors, refrigeration plants, electrical industry, fittings, etc.

AG 309

Nickel alloyed silver filler rod with high silver content for brazing hard metals

TECHNICAL DATA

UTS: 35-59 kgf/mm2

Brazing temperature: 688-816ºC

Elongation: 21%

Electrical conductivity: 9.8 Sm/mm2

TYPICAL APPLICATIONS

Capillary brazing of steels, stainless steel, copper, copper alloys, nickel, nickel alloys and hard metal. Ag 309 is particularly suitable for carrying out brazing operations in the vertical position. Apparatus construction, tool manufacture, brazing of rapid steel and carbide tips. Also suitable for brazing of tungsten, molybdenum and tantalum.

AG 310

Special filler metal with high silver content for brazing hard metals

TECHNICAL DATA

UTS: 39-41 kgf/mm2

Melting temperature: 620-640ºC

Working temperature: 640ºC

Electrical conductivity: 11 Sm/mm2

TYPICAL APPLICATIONS

Joining of steel, stainless steel, copper, brass, bronze, nickel. This filler metal is mostly used for brazing operation requiring a very small melting range. E.g. on precision tools, electrical industry, apparatus construction, etc.

AG 311

Cadmium-free silver brazing filler rod for food industry applications

TECHNICAL DATA

UTS: 35-48 kgf/mm2

Melting temperature: 743-843ºC

Elongation: 25%

Electrical conductivity: 11.2 Sm/mm2

TYPICAL APPLICATIONS

Capillary brazing of steels, stainless steel, copper, copper alloys, nickel, nickel alloys. Food industry, breweries, dairies, apparatus construction, precision machines, precision tool manufacture, refrigeration engineering, aircraft industry, shipbuilding. Suitable for brazed joint operating in seawater.

AG 314

Cadmium-free brazing filler rod with high silver content

TECHNICAL DATA

UTS: 35-49 kgf/mm2

Brazing temperature: 652-760ºC

Elongation: 25%

Electrical conductivity: 7 Sm/mm2

TYPICAL APPLICATIONS

Capillary brazing of steels, stainless steel, malleable cast iron, copper and copper alloys, nickel, hard metal, and also for joints of the above metal amongst themselves. The absence of cadmium makes it especially suitable for joints which come in contact with food, e.g. in dairies, breweries etc. Brazed joint made with this filler metal on stainless steel give the best possible colour matching. Suitable for brazed joints which will operate in seawater.

AG 316

Silver alloy with low melting point

TECHNICAL DATA

UTS: 35-47 kgf/mm2

Brazing temperature: 681-760ºC

Elongation: 16%

Electrical conductivity: 14 Sm/mm2

TYPICAL APPLICATIONS

Capillary brazing on steels, stainless steels, malleable cast iron, copper, copper alloys, nickel, nickel alloys & hard metals; also for joints between the metals named above. Apparatus construction, precision machine parts, shipbuilding, precision tools, joints on copper conductors, refrigeration plants, electrical industry, fittings, etc.