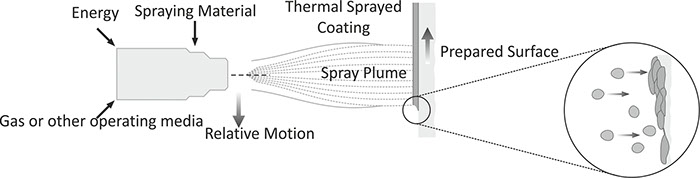

THERMAL SPRAYED COATINGS

The coating material, in powder or wire form, is melted by a heat source and propelled using a stream of gases or compressed air on to the prepared surface to form a coating.

POWDER FLAME SPRAY PROCESS

Material in powder form is melted in a flame (oxyacetylene or hydrogen) and sprayed on a prepared surface.

WIRE FLAME SPRAY PROCESS - METALLIZING

Material in wire form is melted in a flame (oxyacetylene), atomized using compressed air and

sprayed on a prepared surface.

ELECTRIC ARC WIRE SPRAY PROCESS

In arc wire spray process a pair of electrically

conductive wires are melted by means of an electric

arc, molten material is atomized by compressed air

& propelled towards the substrate to form a coating

HVOF (HIGH VELOCITY OXY-FUEL PROCESS)

Coating material in powder form is melted using oxy

-fuel flame and propelled on to the prepared surface at supersonic velocity. Coating material impinges on substrate & cool down to form coating

AIR PLASMA SPRAY PROCESS

Coating material in powder form is melted in a hot

plasma plume and propelled on to a prepared

substrate to form a coating