COPPER & COPPER ALLOYS

TIG/MIG 200

Copper filler rod / wire for oxy-acetylene, TIG/MIG welding of pure copper

TECHNICAL DATA

UTS : 17-28 Kgf/mm2

TYPICAL APPLICATIONS

Used for joining and cladding on copper, e.g. electrolytic copper, pure cooper, Wnr. 2.0060 (E-Cu 57), 2.0070 (SE-Cu), 2.0090 (SF-Cu), 2.0110 (SD-Cu), 2.0150 (SB-Cu), 2.0170 (SA-Cu), 2.1202 (Cu Ag), sheets, profile sections, vessels, pipe lines, etc.

TIG/MIG 200 R

Copper welding filler rod / wire with good flowing properties

TECHNICAL DATA

Source of heat: Oxy-acetylene or TIG torch

Flux: FLUX 200

TYPICAL APPLICATIONS

Copper welding filler metal, tin-alloyed, with good flowing properties-suitable for joining 2.1006 type, pure copper, Cu-metals subject to strain.

TIG/MIG 202

Silicon bronze filler rod / wire for TIG/MIG welding

TECHNICAL DATA

UTS : 35-40 Kgf/mm2

TYPICAL APPLICATIONS

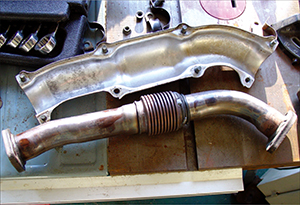

Used for automobile bodies, metro rail coaches, filters, galvanized tanks, deep drawn components for MIG brazing process.

TIG/MIG 203 A

Copper-tin (phosphor bronze) filler rod / wire for welding copper alloys by TIG/MIG processes

TECHNICAL DATA

UTS : 24-37 Kgf/mm2

Source of heat: Welding grade argon/helium

TYPICAL APPLICATIONS

For welding copper alloys such as phosphor bronze, manganese bronze, silicon bronze, yellow brass, naval brass, cast irons, carbon and alloy steels. Also used for bearing bushes, skid rails, Wnr.2.1010, 2.1016, 2.1020, 2.1030, 2.1050, 2.1052, 2.1056, 2.1080, 2.1086, 2.1090, 2.1096.

TIG 204

Copper-Phosphorus filler rod with additives for TIG welding

TECHNICAL DATA

Flux: FLUX 204 (for Cu alloys only)

TYPICAL APPLICATIONS

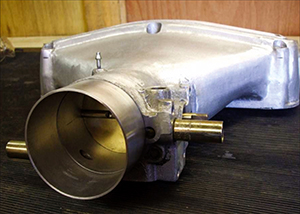

Used for gap brazing copper, brass, bronze etc. No flux needed when brazing on copper to copper. Flux 204 to be used for brazing copper alloys, containers, tubes, apparatus, heat exchangers & boilers.

BRAZE 210

Brass filler rod for brazing of steels, cast iron & copper alloys

TECHNICAL DATA

Source of heat: Oxyacetylene torch, furnace, high frequency induction.

TYPICAL APPLICATIONS

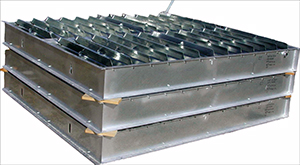

Used for capillary brazing automobile filter elements, brake pipes, pulleys, engine blocks, brass components, galvanized sheets etc.

TIG/MIG 215

Aluminium bronze filler rod / wire for TIG / MIG welding

TECHNICAL DATA

TYPICAL APPLICATIONS

Used for joining and surfacing of aluminum bronze, steels, cast iron and dissimilar metals. Ship propellers, pump impellers, slide gates, fittings, bearings, valves, pump bodies. Metals type Wnr. 2.0916, 2.0920, 2.0928 can also be welded.

TIG/MIG 215 SPL

Aluminium bronze filler rod for TIG/MIG welding

TECHNICAL DATA

UTS : 40-43 Kgf/mm2

Elongation (L=5D) : 40%

Hardness (Brinell) : 100 HB

Melting range: 1030-1040ºC

Electrical conductivity: 7-9 Sm/mm2

TYPICAL APPLICATIONS

Joint and overlay welding of aluminium bronzes, aluminium coated steels, grey cast iron in the machine building and chemical industry, as well as ship building. Joining of corrosion resistant pipes of aluminium bronze or special brass alloys. Overlay welding of ship propellers, slide rails, slip ways and bearings. For multilayer welding on steels, pulsed arc welding is recommended.

TIG/MIG 217

Aluminium bronze filler rod/wire for TIG/MIG welding

TECHNICAL DATA

UTS : 38-46 Kgf/mm2

Melting range: 1030-1040ºC

Electrical conductivity : 8 Sm/mm2

TYPICAL APPLICATIONS

Used for joining and surfacing of aluminum bronze, steels, cast iron and dissimilar metals. Ship propellers, pump impellers, slide gates, fittings, bearings, valves, pump bodies. Metals type Wnr. 2.0916, 2.0920, 2.0928 can also be welded.