RAW MILL & CEMENT MILL

COARSE FEED VALVES/ ROTARY AIR-LOCKS

TOTAL REFURBISHMENT OR NEW MANUFACTURE

AREA OF CONCERN

The body & rotor wears due to heavy grinding abrasion. The gap between rotor blades and body increases making it difficult to control feed rate and smooth operation of rotor.

SOLUTION

Refurbish the body and rotor with added features like use of ‘Hardox’ or ‘Enduraplates’ or ‘Cast-fused’ liners for enhanced resistance to severe abrasion. The performance life is enhanced considerably.

REPAIRING OF GIRTH GEAR CRACKS

CUSTOMER’S FIRST RECALL IN-SITU SOLUTION FOR GIRTH GEAR CRACKS

AREA OF CONCERN

Cracks are normally observed on gear tooth of kiln girth gear, cement mill and raw mill girth gear due to ageing , wear & tear or due to heavy jerking sometime leading to tooth breakage Girth gears are not readily available in stock and is generally made to order with a lead time of 6 months to 1 year thereby leading to downtime loss resulting in production loss with high cost of replacement. Hence reclamation is an ideal solution.

SOLUTION

Job needs to be done in-situ; Crack is tested with NDT (Non Destructive Testing) to ensure no further propagation. Grooves must be prepared to the depth of the crack. A buttering layer with our specialised electrode, LH-1105 ensures purging of all internal impurities. Welding is then completed with our unique product for breakdown LH-521, thereby providing maximum safety margin for this application. Welded component are then finished to the required profile by grinding.

VRM - ROLLERS AND HUBS

TOTAL REFURBISHMENT AT OD &/OR ID OR REPAIR OF CRACKS

AREA OF CONCERN

The OD or ID of roller/ hub gets worn out due to relative motion of tyre or bearings, loosening tyre or bearing or both making the roller inoperational.

SOLUTION

Roller’s MOC is either Cast Steel or Cast Iron. Rebuilding of surface in case of later is very expensive comparative to former. Hence, it is essential to know MOC before we quote. Undercut, heat treatment, WOL build-up, NDT and finished machining is done.

VRM-TYRES AND TABLE LINERS

REBUILDING IS DONE BY WOLPROCESS USING FLUX CORED WIRES

AREA OF CONCERN

The tyre & table liners wear out due to impact and abrasion. The gap between tyre & table liners as well as crushing angle change reducing the output of the VRM thus reducing efficiency & increased power consumption.

SOLUTION

Rebuild the worn-out surface by automated, electronically controlled WOL process using flux cored wires. The WOL deposit is far superior than the base material, metallurgically, offering excellent wear resistance. With our FCW, it is possible to rebuild multiple layers for as high as 80 mm thickness!

SINTERCAST ROLLERCHUNK REPAIR

TOTAL REFURBISHMENT OF ID I.E. BEARING SEAT

AREA OF CONCERN

The latest method for wear protection in a vertical roller mill (VRM) is by sinter cast liners/ rollers. This gives an average life of about 8000-12000 hours after which it needs replacement involving high cost and stoppage, this involves huge downtime and production loss. One of the critical aspects in the sinter cast liners is at times certain rollers get chunked out or chipped off leading to stoppage of the mill, so there is a huge drop in productivity. Hence it requires in-situ welding repair & wear protection solution.

APPLICATIONS

VRM is used for crushing of limestone, coal or clinker (cement plant), sinter cast liners are latest concept wherein the sintered liners are used for wear protection of VRM rollers to increase the life of this rollers-worn out due to high abrasion, pressure and impact.

VRM - SINTER CAST LINERS

LIFE ENHANCEMENT OF VRM -SINTER CAST ROLLERS & TABLE LINERS BY BUTTONING

AREA OF CONCERN

The latest method for Wear protection in Vertical Roller Mill (VRM ) is by Sinter Cast Liners. This gives life of about 8000 -12000Hrs after which it needs replacement. Replacement of sinter cast liners involves high cost and stoppage for replacement & the long lead time for spares, involves huge down time and production loss. The most critical aspect is that the Sinter cast Liners gets worn out and there is a huge drop in productivity. Hence it requires an in-situ wear protection solution.

SOLUTION

Ador Fontech solution to this problem is wear protection of sintercast liners in-situ with unique complex carbide alloy system LH Weartherm 65 which welds on sintercast material giving 65 HRC hardness ensuring extended life with excellent cost economics. Our solution is buttoning in this portion with LH Weartherm 65 in-situ which extends the life by about 3000/3500 hrs with only 10% cost of new sinter cast liners, means it’s a value proposition to customer.

VRM BRIDGE PIPE

ADFL’S UNIQUE SOLUTION FOR VRM BRIDGE PIPE REPAIRS

AREA OF CONCERN

The vertical roller mill (VRM) is used by all major cement manufacturers for grinding limestone, coal & cement. The VRM bridge pipes are used for feeding and discharge of material, these VRM bridge pipe gets cracked due to heavy vibration. Replacement involves high cost and stoppage. The

lead time for spares involves huge downtime and production loss. The most critical aspect of this application is that customers require an in-situ repair with improved life enhancement at shortest possible time.

SOLUTION

Ador fontech solution to this problem is the joining of the crack area of the VRM bridge pipe. The crack occurs in the area of pipe joining the VRM casing & also around the adjoining areas of the pipe. V-grooves are formed in the crack area and aligned and then joining is done by a unique combination of our welding alloy LH-1105 used as a buttering layer & completed joining done by our unique life enhancement alloy LH-521 which combines high tensile strength & high elongation to provide long life to the repaired component.

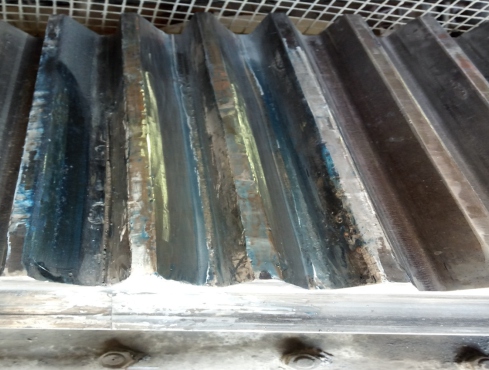

VRM - CLASSIFIER ROTORS

TOTAL REFURBISHMENT OR NEW MANUFACTURE

AREA OF CONCERN

The classifier rotor is subjected to severe, high velocity particle erosion by material being ground in VRM.

SOLUTION

Refurbish the rotor by replacing vanes and hardfacing new vanes for added wear resistance. Other options like use of ‘Hardox’ or ‘Enduraplates’ or ‘Cast-fused’ liners for enhanced resistance to severe abrasion are also available. The performance life is enhanced considerably.

ROLLER PRESS - BEARING HOUSINGS

TOTAL REFURBISHMENT OF ID I.E. BEARING SEAT

AREA OF CONCERN

The ID of the bearing housing wears out due to relative motion between bearing and housing. This results in free rotation of bearing and may cause loss of lakhs of rupees due to seizure or breakage of bearing. The cost of bearing, cost of bearing change and loss of productivity are main concern.

SOLUTION

Refurbish the body at ID and carry out machining.

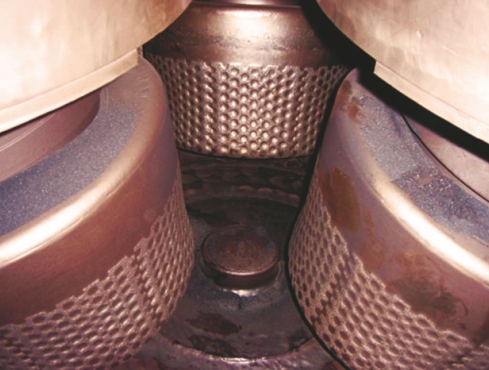

ROLLER PRESS - ROLLERS

TOTAL REFURBISHMENT, IN-SITU PROFILING OR IN-SITU REBUILDING, SHAFT REPAIR

AREA OF CONCERN

- Rollers getting wear out due to heavy handling of material & it’s abrasiveness, under very high pressure. The gap between rollers increases making it difficult to control required size.

- Chunks of base material coming out of roller, disturbing it’s balance and grinding efficiency.

SOLUTION

Refurbish roller by removing old deposit, rebuilding it by automated WOL process and profiling – all in controlled welding conditions and temperatures. The performance life is enhanced considerably and we ensure that Chunks won’t come out during operation.