NICKEL & NICKEL ALLOYS WELDING ELECTRODES

LH-GOLD 555

Critical repair and maintenance welding of nickel alloys & dissimilar combination of steels

TECHNICAL DATA

Tensile Strength : 1,00,000 PSI

Elongation : 45%

Bend results (3x90OC free-bend test) free from fissures & cracks

TYPICAL APPLICATIONS

LH-GOLD 555 is a specially formulated alloy with a high percentage of nickel, chromium & manganese. Deposits offer extraordinary combination of properties which include: High ductility, High impact resistance, Minimum base metal dilution, Extraordinary thermal stability and Excellent corrosion & oxidation resistance.

LH 501

Electrode for welding pure nickel

TECHNICAL DATA

UTS: 41-45 kgf/mm2

Elongation: 20-25%

TYPICAL APPLICATIONS

Used for welding of pure nickel and nickel- plated steels. Overlay of nickel on steel. Joining copper and copper alloys with steel. Apparatus construction, chemical industry, valves and pipe lines.

LH 511

Electrode for welding monel (nickel-copper) alloys

TECHNICAL DATA

UTS: 48-55 kgf/mm2

Elongation: 30-35%

TYPICAL APPLICATIONS

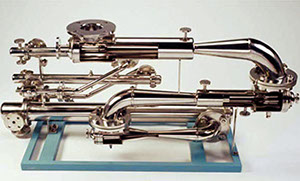

Used for joining & cladding Monel, alloy steels, dissimilar steels. Suitable for welding following grades: Wnr. 2.4360, 2.4374, 2.4400, valves, pumps, impellers, etc.

LH 512

Cuppro-Nickel electrode for seawater corrosion resistance

TECHNICAL DATA

UTS: 35-40 kgf/mm2

Elongation: 20-26%

TYPICAL APPLICATIONS

Used for joining & cladding similar grades of copper-nickel alloys, with up to 30% nickel content. Shipbuilding, food industry, desalinization plants, refrigerators, heat exchanger, pumps, valves, pipelines, etc.

LH 521

Ni-Cr-Fe basic coated stick electrode for heat resistance

TECHNICAL DATA

UTS: 55-60 kgf/mm2

Elongation 30-35%

TYPICAL APPLICATIONS

This is a versatile electrode for welding of nickel, inconel, monel, nickel-chromium-iron alloys. Weld deposits are similar to ENiCrFe3. HK alloys, steel, stainless steel and heat resisting steels. Also for welding dissimilar metals such as carbon steels, stainless steels, nickel, nickel alloys to each other. For use on equipment and components made of pure nickel, for fabrication of corrosion resistant tanks and containers, heat exchangers, furnace components, boilers, fittings, anchors, mill trunnions, symmetry gears, etc. Very good for repair of cracks in kiln tyres.

LH 521 A

Nickel based Molybdenum bearing electrode for tough, heat and corrosion resistant joints

TECHNICAL DATA

UTS: 55-60 kgf/mm2

Elongation: 30-35%

TYPICAL APPLICATIONS

Electrode for all-position welding of nickel, inconel, monel, nickeliron- chromium alloys. HK alloys, stainless and heat resisting steels. For use on equipment and components made of pure nickel, for fabrication of corrosion resistant tanks and containers, heat exchanger, furnace components, etc.

LH 524

Ni-Cr-Mo stick electrode with basic flux coating for temperature and corrosion resistance

TECHNICAL DATA

UTS: 76-80 kgf/mm2

Elongation: 30-35%

TYPICAL APPLICATIONS

To join and hard-surfacing of identical or similar grades of heat-resisting steels and alloys. Also for welding alloy steels like H 11, H 13, 17 Mn 4, St E 355, 15 Mo 3, 15 Mn Ni 6 3, 13 Cr Mo 4 4, 10 Cr Mo 9 10 u. X 8 Ni 9. Specially

suitable in sea water and offshore plants, chemical-engineering (nitric, sulphuric, hydrochloric, phosphorous acid as well as alkalis), flue gas dust collectors.