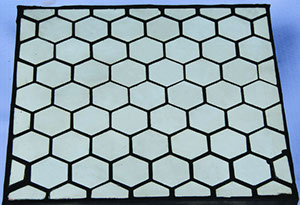

RUBBER BACKED CERAMICS

Alumina ceramics are harder than steel and are suited for abrasive sliding applications. However, ceramics are brittle by nature. In order to overcome this limitation, ceramics are hot vulcanized in to rubber to make a ceramic rubber composite. The extremely hard ceramic provides resistance to wear and the elastic properties of rubber dampen the impact forces.

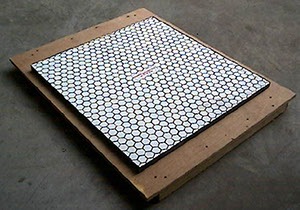

Typical applications of rubber backed ceramics are Transfer Chutes, Wagon Tipplers, Dump Hoppers, Diverter Gates, Feed Chutes and any such applications, where mild impact and severe abrasion are a problem.

FEATURES

- High alumina tiles eliminates wear completely

- Smoothness of tiles ensures free flow of bags and avoids tearing of bags

- Since tiles are vulcanized in rubber it can take impact because of cushioning effect of rubber.

- Reduces operating cost.

- In –situ installation.

- Consumes less volume because of 3mm thickness.

- Ceramic Rubber Mats are extensively used in Cement Bagging Plants.