HARD FACING WELDING ELECTRODES

LH 708

Hot work tool steel electrode

TECHNICAL DATA

Hardness (as welded) 41-46 HRC

(after hardening) 49-51 HRC

(after annealing) 21-24 HRC

TYPICAL APPLICATIONS

Used for repair of tools of similar materials or fabrication of hot work tools of carbon steels or low alloy steels, dies, stampers for non-ferrous metals, saddle tracks, forging hammers, distributor pins, slides, hot shear blades, trimming dies, etc.

LH 710

Electrode for tough and wear-resistant against friction

TECHNICAL DATA

Hardness: 29-35 HRC

TYPICAL APPLICATIONS

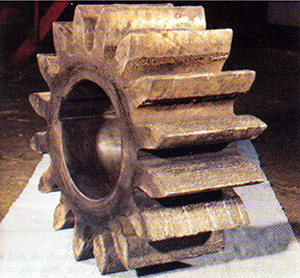

Surfacing of parts subject to wear by friction and mild impact. Rims, carbon-alloyed rails, dies, striking tools, rolling surfaces, sliding surfaces subject to heavy wear, stampers, etc. also ideally suited for construction & mining machinery parts like drive sprockets, rollers, concrete mixer blades, pump shaft, conveyor, screws, pinions and girth gear. The right choice for providing buffer layers where friction, mild impact and abrasion occur together.

LH 710 BF

Specially designed electrode for surfacing of dies and tools in forging industry

TECHNICAL DATA

Hardness: 38-42 HRC

TYPICAL APPLICATIONS

Forging dies for filling all types of die impressions or cavities. Joining and buildup on all drop-forging tools such as punches, dies, inserts, etc. Repair of damaged or worn out profiles. Salvage of scrapped / undersized die blocks by rebuilding totally with weld metal.

LH 713

Austenitic manganese steel electrode for high impact resistance

TECHNICAL DATA

Hardness as welded 17 HRC

work hardened 40-45 HRC

TYPICAL APPLICATIONS

For joining manganese steel/ Had field steel parts and hardfacing of parts subject to heavy impact and stress. Recommended for crushing equipment parts like rocks, jaws, cones, gyratory crushing mantles, excavator teeth, manganese rails, hammers, buckets, etc.

LH 714 S

High deposition manganese steel electrode

TECHNICAL DATA

UTS: 80-85 kgf/mm2

Hardness as welded: 17-20 HRC

work hardened: 42-50 HRC

Metal Recovery: 140%

TYPICAL APPLICATIONS

For joining manganese steel parts, hard facing of parts subject to heavy impact and stress. For all position welding of 14% Mn steels, armour steels, carbon steels, Had field Steel. Ideal as buffer layers before surfacing on 14% Mn steels, hard or unidentified steels. Very thick build-ups possible without cracking. Specially developed for mining industry.

LH 715

Hardfacing Electrode with high speed steel deposit

TECHNICAL DATA

Hardness as welded 59-61 HRC

work hardened 62-64 HRC

annealed 25-30 HRC

TYPICAL APPLICATIONS

For repair and manufacture of cold and hot cutting tools, trimming dies, broaches, punching tools, drills, milling tools, hot dies, etc.

LH 717

Corrosion and oxidation resistant for surfacing & joining

TECHNICAL DATA

UTS: 70-75 kgf/mm2

Elongation: 25-30%

Hardness as welded: 20-24 HRC

work hardened: 42-48 HRC

Metal recovery: 150%

TYPICAL APPLICATIONS

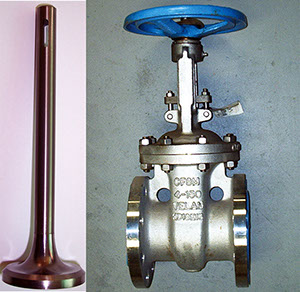

Fabrication and repair of hot pressing tools as well as surfacing of parts subject to abrasion, oxidation and corrosion. Drop forge dies, hot trimming tools, pump impellers, valves. Ideal for crack-free welding of parts subject to thermal and chemical influence, i.e., for joining of heating elements.

LH 718

Electrode for abrasive and corrosive conditions at elevated temperatures

TECHNICAL DATA

Hardness: 48-50 HRC & at 500O C 30-35 HRC

TYPICAL APPLICATIONS

For surfacing of blast furnace bells and hopper, tong pins, hot shears, etc. to resist severe abrasion specially at elevated temperatures.

LH 720

Surfacing electrode with chromium carbide for abrasion resistance

TECHNICAL DATA

Hardness: 58-62 HRC

TYPICAL APPLICATIONS

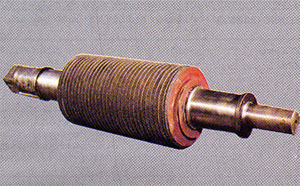

Wear resistant surfacing of mild and low alloy steels: Building up machine parts, digger teeth, bucket teeth & edges, conveyer screws, mixer wings, oil expeller worms, scrapper blades, cement die rings, muller tyres, plough shears & mining applications.

LH 721

Alloy containing tungsten carbides

TECHNICAL DATA

Hardness on WC matrix: 70-75 HRC

Hardness on weld deposit 60-62 HRC

TYPICAL APPLICATIONS

Surfacing of parts subject to heavy abrasion and erosion. Oil drilling stabilizers, earth moving equipment, cutting hard rocks, etc. Ideal for coal, coke and slag processing plants, wing bits, shovel teeth, oil drill tools, blades, mixers, etc. Excellent for surfacing of parts used in mines containing high silica deposits.

LH 725

Surfacing electrode with chromium carbide deposits

TECHNICAL DATA

Hardness: 60-65 HRC

TYPICAL APPLICATIONS

Ideal for agitator blades, scrapper blades, conveyor screws, clay extruder screws. Coal crusher rolls in thermal power plants, oil expeller worms, tooth points and buckets of excavators, digger teeth, bucket tip edges, cement die rings, muller tyres, plough shears, crusher hammers in cement plant, Chinese long walls in underground mines. For components subject to metal to metal wear and abrasion with mild impact likely to be absorbed elastically. Surfacing of mild and low alloy steels for wear resistant properties.

LH 726 B

Special cobalt-based alloy for surfacing plain carbon and alloy steels

TECHNICAL DATA

Hardness: 35-40 HRC

TYPICAL APPLICATIONS

Surfacing of work-pieces requiring high corrosion, oxidation, heat and impact resistance. Surfacing of valves, conveyer screws, knives, hot-shearing blades, dies, cutting edges, e.g., in chemical, rubber, oil and sugar industries as well as in steel mills.

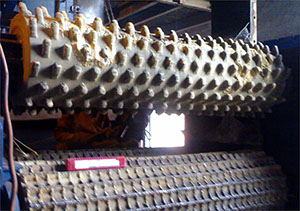

LH 738 S

Spray type, extra high, wear-resistant electrode having complex carbides with globular deposition

TECHNICAL DATA

Hardness:57-61 HRC

TYPICAL APPLICATIONS

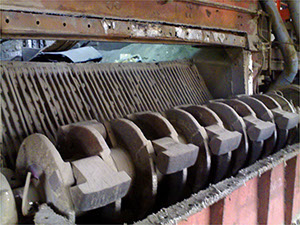

Primarily for “Spot-Arc” building / roughening the chilled cast iron rolls in the sugar mills. Also for reclamation of sand mixing blades, scrapers, screw flights, mixing paddles, etc.

LH 743 N

Electrode with high chromium carbide deposit for excellent resistance to abrasion and heat

TECHNICAL DATA

Hardness:55-60 HRC

TYPICAL APPLICATIONS

Hard surfacing of parts which are subject to severe abrasive wear and moderate shocks. Conveyer screw flights, mixer blades, auger screws, dredging cutter, runner bottom edge, pug mill, blast furnace bells & hoppers.

LH 743 S

Hard surfacing electrode with very high metal recovery for excellent resistance against abrasion

TECHNICAL DATA

Hardness: 57-61 HRC

Metal recovery: 180%

TYPICAL APPLICATIONS

For hard facing of parts subject to heavy abrasion and metal to- metal wear with mild impact and temperature up to 650ºC. Suitable for: refractory press screws, palm oil expeller flights, conveyor screws, impellers, dredging cutter & drag head, runner bottom edge, pug mill, knife, wing knife, auger, boring bits, blast furnace bells and hoppers, clinker crusher hammers and rotors.

LH 745 S

Surfacing electrode with exceptional hardness and abrasion resistance

TECHNICAL DATA

Hardness: 57-63 HRC

Hardness at 600ºC: 40-43 HRC

Metal recovery: 190-210%

TYPICAL APPLICATIONS

For surfacing of hopper and protection plates in quarries, ore crushing rolls, gyratory crusher mantles, ore breaker teeth, scraping beaks, sinter plant disintegrators, blast furnace bells and hoppers, chutes, sinter breaker stars and grizzly bars etc.

LH 7141

High deposition efficiency manganese steel electrode specially designed for surfacing rail crossings

TECHNICAL DATA

UTS: 75-80 kgf/mm2

Hardness as welded: 15 HRC

work hardened 42-55: HRC

TYPICAL APPLICATIONS

For welding of 13% Mn steel rail crossing where minimum 15 GMT life of the rail crossing is required. For welding bullet proof arm our quality steel plate. For welding hard or unidentified steels. For heavy, crack free buildups. The electrode can be used for dissimilar joints consisting of high manganese and other steels.

LH 7191

High tensile, tough, austenitic manganese steel alloy

TECHNICAL DATA

UTS: 75-82 kgf/mm2

Elongation: 30-35%

Hardness as welded: 17 HRC

work hardened: 55 HRC

TYPICAL APPLICATIONS

For surfacing Mn Steel, rail points and crossings, frogs, switches, etc., where minimum 25 GMT is required. Rebuilding 14% Mn steel components (earth moving equipment). For welding of bullet proof armour steel, joining dissimilar steels such as high Mn steel and carbon steel. Ideal alloy for surfacing castings of hadfield steel.

LH 7450

Electrode with extreme resistance to abrasion at high temperatures

TECHNICAL DATA

Hardness: 62-66 HRC at ambient temp

Hardness: 40 HRC at 630ºC

Metal recovery 230%

TYPICAL APPLICATIONS

Sinter-handling equipment, blast-furnace bells and hoppers, clinker conveyor chains, cokepusher shoes, excavator buckets, gyratory crusher mantles, etc.

LH 7461

Highly abrasion-resistant, hard-surfacing electrode with very high metal recovery

TECHNICAL DATA

Hardness: 55-62 HRC

TYPICAL APPLICATIONS

LH 7461 Hardfacing electrode is specially designed for applications where welds have to withstand heavy abrasion in service and metal-to-metal wear. For surfacing of ore-crushing rolls, gyratory crusher mantles, ore-breaker teeth, scraping beaks, sinter plants, disintegrators, etc.