ALUMINIUM & ALUMINIUM ALLOYS

TIG/MIG 400

Pure aluminum filler rod / wire for oxy-acetylene, TIG and MIG welding processes

TECHNICAL DATA

Source of heat: Oxy-acetylene/TIG torch

Flux: Flux 200 (paste)

TYPICAL APPLICATIONS

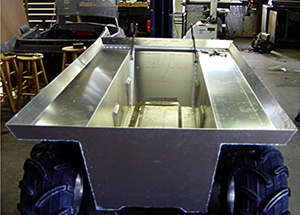

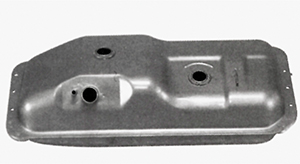

Used for welding pure aluminum, 1000 series, Al 99.8, Al 99.7, Al 99.5,E-Al. Tanks, brackets, bus bodies etc. Preheat thick plates (over 15 mm) to 150ºC.

TIG/MIG 401

Al-Mg filler rod / wire for TIG / MIG welding-high strength and resistance to seawater corrosion

TECHNICAL DATA

TYPICAL APPLICATIONS

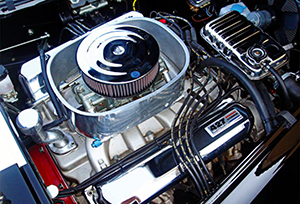

Used in ship building, off shore, cryogenic equipment, aluminum bridges, railway constructions, automobile industry, welding of AlMg 4, 5Mn, AlMg

5, AlMg 2MnO2, AlZnMg1, AlZnMgCuO,5, AlMgSiO, 5, AlMgSil, G-AlMg10,

G-AlMg5, G-AlMg3Si, G-AlMg5 Si.

TIG/MIG 402

Al-Mg filler rod / wire for TIG / MIG welding processes

TECHNICAL DATA

TYPICAL APPLICATIONS

Used for welding aluminum magnesium alloy base metal. All elements of this alloy are closely controlled for optimum weld strength. Applications in

defense, general constructions, marine and structural industry. Welding of rolled and cast Al- Mg alloys such as AlMg4.5 Mn, AlMg5, AlZn4.5Mg1, AlMg5 Mn, AlMg2.7Mn, AlMgSi1 can be accomplished.

TIG/MIG 404

Al-Mg alloy filler rod / wire for TIG / MIG welding processes

TECHNICAL DATA

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

Used for welding aluminum magnesium alloy base metal as per DIN 1725

Bl. 1 and Bl. 2, e.g. Al Mg 3, Al Mg 5, Al Mg Mn, Al Zn Mg 1, G-Al Mg 3/ +Si/ + Cu, G-Al Mg 5/ +Si, G-Al Mg 10, Al Mg Si1. Tank construction, aluminum structures, vehicle body building, shipbuilding, window manufacture etc.

Preheat plates exceeding 15 mm thickness to at least 150ºC.

TIG/MIG 405

Al-Si alloy filler rod / wire for TIG / MIG welding processes

TECHNICAL DATA

Electrical conductivity: 21 Sm/mm2

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

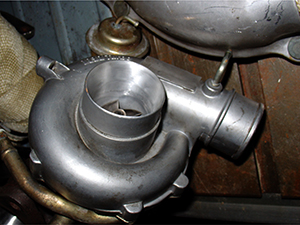

Used for welding Al Si 5, Al Mg Si 0.5, Al Mg Si 0.8, Al Mg Si 1. Al & alloys with less than 2% alloying elements, cast aluminum alloys with up to 7% silicon content. Preheat plates exceeding 15 mm in thickness to approx. 150ºC.

TIG/MIG 406

Al-Cu filler rod / wire for TIG / MIG welding processes

TECHNICAL DATA

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

TIG/MIG 406 used for naval applications, instruments, tanks, radars etc.

TIG/MIG 407

Al-high Silicon filler rod / wire for TIG/MIG welding processes

TECHNICAL DATA

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

Used for welding cast aluminum alloys with more than 7% Si content. Tank construction, air conditioning equipment, domestic appliances, plates, tubes, profile sections. Preheat thick plates and large work pieces to approx. 150-180ºC.

TIG/MIG 408

Al-Si alloy filler rod / wire for TIG / MIG welding processes

TECHNICAL DATA

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

Used for repairs and filling up cavities on Al-Si castings with more than 7% Si content. In special cases aluminum alloys with less than 2% alloying elements are also welded.

TIG/MIG 804

Al-Mg alloy filler rod / wire for TIG / MIG welding processes

TECHNICAL DATA

TYPICAL APPLICATIONS

Used for welding aluminum magnesium alloy base metal as per DIN 1725

Bl. 1 and Bl. 2, e.g. Al Mg 3, Al Mg 5, Al Mg Mn, Al Zn Mg 1, G-Al Mg 3/ +Si/ + Cu, G-Al Mg 5/ +Si, G-Al Mg 10, Al Mg Si1. Tank construction, aluminum structures, vehicle body building, shipbuilding, window manufacture etc. Preheat plates exceeding 15 mm thickness to at least 150ºC.

TIG/MIG 805

Al-Si alloy filler rod / wire for TIG / MIG welding processes

TECHNICAL DATA

Melting range 570-625ºC

TYPICAL APPLICATIONS

Used for welding Al Si 5, Al Mg Si 0.5, Al Mg Si 0.8, Al Mg Si 1. Al & alloys with less than 2% alloying elements, cast aluminum alloys with up to 7% silicon content. Preheat plates exceeding 15 mm in thickness to approx. 150ºC.

TIG/MIG 807

Al-high Silicon filler rod / wire for TIG/MIG welding processes

TECHNICAL DATA

Melting range: 590-625ºC

Electrical conductivity: 21 Sm/mm2

Shielding gas: Welding grade argon

TYPICAL APPLICATIONS

Used for welding cast aluminum alloys with more than 7% Si content. Tank construction, air conditioning equipment, domestic appliances, plates, tubes, profile sections. Preheat thick plates and large work pieces to approx. 150-180ºC.