STEEL WELDING ELECTRODES

LH 103

A contact electrode for speedy, all-position welding of mild steel

TECHNICAL DATA

UTS: 45-51 kgf/mm2

Elongation: 17-20%

TYPICAL APPLICATIONS

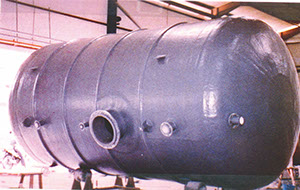

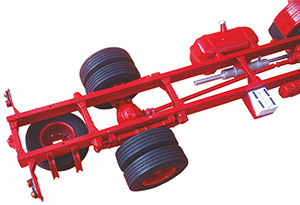

Auto-bodies, chassis, steel doors and windows, steel furniture, storage tanks, pipes, sheet metal works, etc. Best suited for bridging wide root-gaps.

LH 104

Low hydrogen steel welding electrode for medium tensile, ductile steel welds

TECHNICAL DATA

UTS: 50-58 kgf/mm2

Elongation: 22-29%

TYPICAL APPLICATIONS

Steel welding Electrode used for joining and building up of low and medium carbon steels. Ideal for joining dissimilar sections, restrained joints and oil soaked parts, castings. Can also be used as a cushioning alloy under hardfacing deposits. Finds applications in pressure vessels, pipes, flanges, vehicle chassis, cross members, gun plates, heavy machinery parts, steel castings, C-frames, H-frames, crusher rotor discs, etc.

LH 105 LMP

Steel welding electrode for low and medium carbon steels as well as medium tensile steels of various compositions.

TECHNICAL DATA

UTS: 50-54 kgf/mm

Elongation (L=4d): 22-30%

TYPICAL APPLICATIONS

For welding of low and medium carbon steels and medium tensile steels of various composition. Steel welding electrode for welding pressure vessels, pipe welding, fabrication and repair welding of heavy machinery parts, steel castings, sluice gates, etc. For heavy restrained joints where minimum distortion is desired. An excellent electrode for repair at site, for repairs at dams, power stations, etc.

LH 106

Universal Steel welding electrode to weld known & unknown combinations of steels

TECHNICAL DATA

UTS: 75-85 kgf/mm

Elongation: 22-26%

TYPICAL APPLICATIONS

Steel Welding applications include Heavy machinery parts, earthmoving equipment parts, automobile springs, trunnions of cement mills, parts subject to heat, corrosion and impact.

Joining and surfacing of high carbon, low and high alloy steels, tool steels, spring steels, manganese steels, case hardened steels, high speed steels, cast steels, difficult to weld steels and unidentified steels. Joining dissimilar steels. Surfacing of grooved rolls and repair of dropforge dies. Used as cushioning alloy under-hard deposits.

LH 106 SMP

Austeno-ferritic electrode with excellent ductility and high tensile strength for all types of steel welding

TECHNICAL DATA

UTS: 70-90 kgf/mm2

Elongation: 22-25%

TYPICAL APPLICATIONS

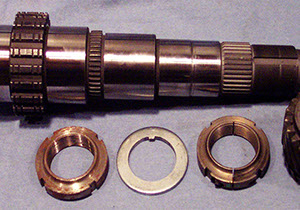

For joining dissimilar steels of unknown composition with different thickness, welding of dies, springs, shaft splines, gears, punches, etc. For depositing cushioning layer on difficult to weld steels before depositing final surfacing layer.

LH 107

Steel welding electrode for high resistance to heat and corrosion

TECHNICAL DATA

UTS: 55-65 kgf/mm2

Elongation: 30-35%

TYPICAL APPLICATIONS

Used for joining and surfacing of all types of steels, alloy steels, heat, scale resistant steels, manganese steels and dissimilar steels. As a cushioning layer under hard deposits, fabricating and repairing of valves, rolls, gears, hot dies, gas turbines, parts subject to heat, corrosion and impact. Cladding Carbon steels, hydrogenation plants, combustion chamber parts, furnace parts, etc.

LH 108

Steel welding electrode for welding austenitic manganese steels

TECHNICAL DATA

UTS: 58-65 kgf/mm2

Elongation (L=4d): 30-40%

TYPICAL APPLICATIONS

Used for joining Austenitic Manganese Steels (14% Mn). Ideal for joining Austenitic Manganese Steels to Mild Steels, Difficult Steels, High Alloy Steels, etc. Ideal for providing ‘Elastic Interlayer’ – (cushioning layer) before hard surfacing. Surfacing manganese steel rails. Repairing cracks in austenitic manganese steel castings, joining buckets cracks on earth moving equipment in mining industry.

LH 109

Steel welding electrode for joining SS to Carbon Steel and for depositing SS overlays on Carbon Steel

TECHNICAL DATA

UTS: 55-65 kgf/mm2

Elongation: 30-35%

TYPICAL APPLICATIONS

Used for joining stainless steels to carbon steels, low alloy steels, cast steels and austenitic manganese steel parts. Depositing stainless tough overlay on cast steel parts, austenitic manganese steel parts. Rebuilding of impellers, shafts, valve bodies, seats and turbine guide vanes to provide resistance to heat, erosion and corrosion.

LH 1061

Austeno-ferritic, highly crack-resistant electrode having high tensile strength for all types of steel welding

TECHNICAL DATA

Tensile Strength: 1,20,000 PSI

Elongation: 22-26%

TYPICAL APPLICATIONS

Used for joining or surfacing of any carbon steel of unknown composition. Suitable for welding all types of low and high-alloy steel, tool steel, spring steel, manganese steel, high-speed steel, case-hardened steel. Recommended for joining dissimilar steels.

LH 1105

Extra low hydrogen controlled electrode with good ductility and creep resistance for steel welding

TECHNICAL DATA

UTS: 55-65 kgf/mm2

Elongation: 25-30%

Charpy v-notch impact strength: 140-200 J

TYPICAL APPLICATIONS

Very good for repair of cracks in kiln tyres. Kiln shell welding, under-carriage frames of heavy earth moving equipment, high pressure pipelines, sluice gates, boiler tubes and boiler plates where good creep resistance is necessary for welding German Steels HIV 15 Mo3, etc. The electrode can be used for welding low-alloy steels in thermal-power stations, especially for welding of tubes in heat-exchangers, welding carbon steels of unknown composition.

LH 1106

Austeno-ferritic alloy steel electrode for high strength and crack-resistant welds for all types of steel welding

TECHNICAL DATA

UTS: 70-80 kgf/mm2

Elongation (L=4d) 30-32%

TYPICAL APPLICATIONS

Most suitable for joining armour steel, Austenitic Manganese steel, cast steel, forged steel and stainless steel to carbon steel or steels of unknown composition. For surfacing of grooved rolls, springs, dies, punches, crowns and repair of drop forged dies and also as a cushioning layer before hard facing.