Nickel- Of Vital Importance in Cast Iron Welding

Table of Contents

- Cast Iron in Industry

- Advantages of Cast Iron

- Disadvantages of Cast Iron

- Applications of Cast Iron

- Importance of Repairing Cast Iron Components

- Why is Nickel Vital to the Repair?

- Ador Fontech expertise in Cast Iron Welding

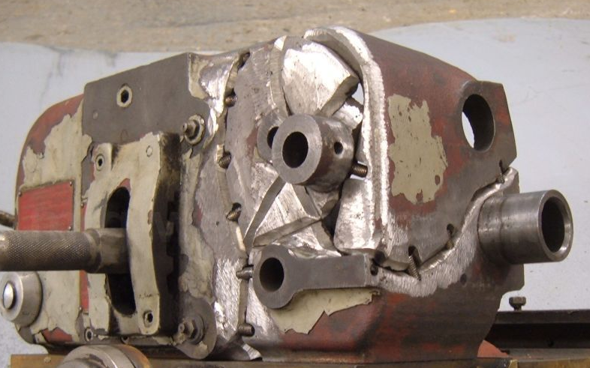

The main problem with welding cast iron comes from its high carbon content. During the welding process, this carbon migrates into the weld metal and/or the heat-affected zone adjacent to the weld metal, making it hard & brittle. This is how Cast Iron gets its reputation for post-weld cracking.

Hence the key to welding cast iron lies in eliminating the risks posed by this higher carbon content which reduces its elongation to about 1%.

Cast Iron in Industry:

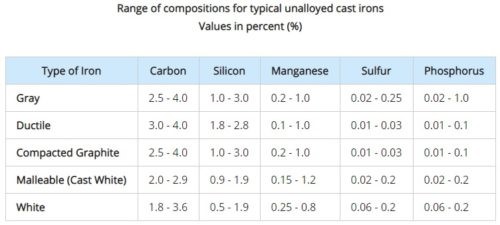

Cast iron is a ferrous alloy that has more than 2% carbon in it. Though it can contain anywhere from 2% to 6.67%of carbon, practically it is found to be between 2% to 4%. Other alloying elements & types of Cast Iron used generally are listed in the table below:

Advantages of Cast Iron

•It has good casting properties.

•It is available in large quantities, hence produced on a mass scale. Tools required for the casting process are relatively cheap and inexpensive, resulting in low cost of products.

•It can be given any complex shape and size without using costly machining operations.

•It has three to five times more compression strength compared to steel.

•It has good machinability (gray cast iron)

•It has excellent anti-vibration (or damping) properties, hence it is used to make machine frames.

•It has resistance to deformation.

Disadvantages of Cast Iron

•It is prone to rust & loss of Strength.

•Its parts are section-sensitive; due to the slow cooling of thick sections.

•Failure of its parts can be sudden and total parts are crack sensitive

•It has high brittleness.

Applications of Cast Iron

Cast iron is used in making the following products

•Pipes, to carry suitable fluids.

•Different machines

•Automotive parts

•Pots, pans and utensils

•Anchors for ships

•Machine bases

Importance of Repairing Cast Iron Components:

Cast iron is widely used in diverse industries with its inherent advantages. It is crack sensitive and also has a reputation of being difficult to weld because of its high percentage of carbon and less conductivity. It is also one of the prime examples for Ador Fontech to showcase our product & process expertise. We not only overcome this problem to successfully repair cast iron components but also give them an even better life than the original components.

Why is Nickel Vital to the Repair?

Nickel-based alloys & high Nickel electrodes are basically used in the welding of all weldable cast Iron as its offers excellent solubility of its carbon component and it’s also a more ductile weld metal. Nickel electrodes also help to reduce the pre-heating and HAZ cracking by providing less carbon pick up in the weld area & the heat-affected zones around weld joints. In all cases, care should be taken to minimize heat input to the base metal. Hence Low Heat Input Welding Alloys like LH 119 & LH CastHeal 113F offer the best solution totally eliminating post-weld cracks. They give a safe and sound joint with considerable Life Enhancement to any broken component.

Ador Fontech expertise in Cast Iron Welding:

From the moment we started our operations in the maintenance & repair welding business 4 decades ago, we had introduced novel products for welding cast iron with products like LH 115 & LH 119. These alloys offer special low heat input properties and unparalleled performance in the last 40 years with our unique methodology of cold welding in Cast Iron components with proprietary expertise in hand heat method.

Today, we offer a complete range of Nickel Alloys in welding Electrodes and in wire form, both TIG and MIG, to take care of all the welding needs of our valued customers. We, at Ador Fontech, take pride in saving thousands of components with our Low Heat input-LH Philosophy to ensure savings in inventory and higher productivity through the Life Enhancement of repaired components.

Reclaim, Do Not Replace