KILN

KILN - TYRE CRACK REPAIR

IN-SITU REPAIR OF ALL CRACKS DETECTED IN KILN TYRES

AREA OF CONCERN

The crack may develop rapidly in tyres if the Kiln is continued to work. Tyres are casted and not readily available. Lead time to supply may vary from 4 months to a year and mostly imported. Huge down time resulting in production loss as well as cost involved in tyre replacement. Developed CREEP may cause further damage to other parts of Kiln if tyre is allowed to run without repair.

SOLUTION

Detect and repair cracks in tyre, carry out PWHT and run the kiln till new tyre arrives. Ador has performance proven welding consumables & Quick Response Team to undertake this repair work.

KILN - SHELL JOINTS BY SAW

CARRY OUT WELDING OF SHELL JOINTS BY AUTOMATED PROCESS THUS REDUCING PRECIOUS SHUT-DOWN CONSIDERABLY AND HUGE SAVING WITH HIGHEST QUALITY WELD JOINTS

AREA OF CONCERN

MMAW of joints may take up to 6 to 8 days depending upon diameter and thickness of shells. Thus, warranting more time for shutdown. This is an essential activity and can’t be avoided. Being MMAW, quality of welding within a joint itself may vary depending upon welder’s skill. Uneven fusion, slag inclusion, under bead cracking development of stresses and non-uniformity of welding may lead to bad quality.

SOLUTION

Deployment of SAW process cuts down welding time by at least 4 to 5 days! Thus, saving lots of shut-down time. Strictest control over welding parameters ensure uniform weld bead quality, generation of lesser/negligible stresses and almost ZERO defects.

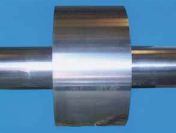

KILN - SUPPORT AND THRUST ROLLS

TOTAL REFURBISHMENT WORN OUT ROLLERS OR REPAIR OF CRACKS

AREA OF CONCERN

ADFL offers rebuilding of barrel of rollers and repair of shafts, at the same time maintaining surface finish, critical dimensions and stress-free component. Refurbishment is done by welding as well as thermal spray coatings.

SOLUTION

ADFL offers rebuilding of barrel of rollers and repair of shafts, at the same time maintaining surface finish, critical dimensions and stress-free component. Refurbishment is done by welding as well as thermal spray coatings.

KILN - JOBS ON TURN-KEY BASIS

FABRICATION & REPLACEMENT OF KILN SHELLS, COWL, TYRES, GIRTH GEAR CHANGE OR REVERSAL ETC.

TECHNICAL DATA

None. ADFL offers turn-key solution with fabrication and services at one stop.