Process industry generally requires the mineral ore’s needs to be processed. In other words, it needs to be crushed into a near powder form from its natural state. Typically, if you take an example from the cement industry, limestone extracted from mines is crushed close to a powder form before it moves on for further processing in grinding mills and then fed into a kiln from the cement-making process. The mines where the crushers are located form the backbone of the industry, making it a vital area for refurbishment as wear rates are very high due to high abrasion & impact caused by abrasive materials.

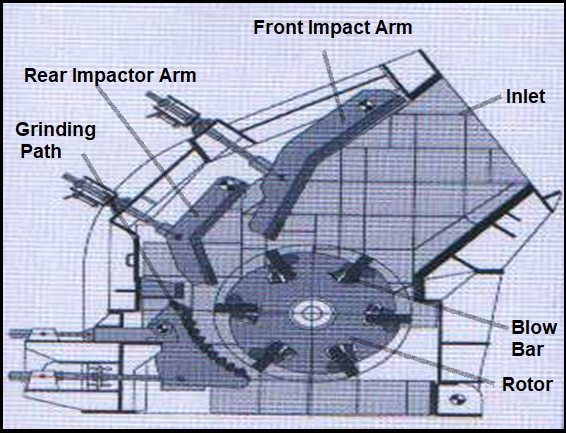

The most widely used and most efficient crusher machinery system for this task is the Hydraulic Impact Crusher. Nowadays this is predominantly used in Cement Industry as this simplifies crushing by doing the work of both primary & secondary crushers earlier used in the industry. The working process is very simple. Limestone ore is fed into the Horizontal Impact Crusher inlet as it falls into the rotating rotor. Then it gets crushed by the blow bar, inside the impact crusher during the crushing process, the front impact arm ensures the compressive loading of the ore. The rear impactor Arm & Grinding path ensures the fine crushing of limestone for further processing.

View of Horizontal Impact Crusher:

The main wear factors acting on the component are High Abrasion & Impact with compressive loading inside the Horizontal Impact Crusher. The main components get worn out are the front & rear impact arms or impactor arms, grinding path, blow bars, and the rotor body. So all these parts require a complete refurbishment to get the required profile to keep the crushing efficiency & also at the same time ensuring Life Enhancement of the worn-out components.

The best solution in the industry to give wear protection to all worn-out components is the unique single electrode solution developed by Ador Fontech LH TUFF-TECH 58 for high abrasion & high impact application. LH TUFF-TECH 58 is the ideal alloy for this application since its titanium carbide alloy system in martensitic matrix gives the best wear resistance to abrasion combined with impact outperforming all conventional hardfacing methodologies.

With this single titanium carbide alloy system LH TUFF-TECH 58, ADFL has replaced the conventional two electrode combination used as base layer & final layer. The most important aspect is that LH TUFF-TECH 58 outperforms all conventional Alloys with increased life by almost 40% as it gives superior wear resistance to this high abrasion & impact application.

The critical advantage with Ador Fontech is that the job can be executed at customer premises while complete refurbishment can be done at our Premises Life Enhancements services facility in Nagpur. Also, for greater customer convenience, this job can be executed through our authorized repair shops at locations close to the plant with trained manpower completely under our supervision.

The complete refurbishment of the horizontal impact crusher is a critical component highlighting the Ador Fontech way of life enhancement of industrial components. Our specially formulated wear solutions ensure Life Enhancement with maximum safety margin at a marginal cost of replacement giving the best value proposition to customers.

Reclaim –Do not replace

2. Scrapping

2. Scrapping