Table of Contents

- Primary Wear Factors

- Secondary Wear Factors

In any discussion of welding on wear-prone applications, reference is made to the hardness of weld deposits & what hardfacing electrode can be used for different applications. But the word “hard facing” is actually a misnomer. In reality, what any maintenance engineer in any plant is looking for is an ideal solution to tackle the wear in the particular application. So, in essence, the engineer is looking for a wear-facing product with the necessary properties to tackle the wear. not just hardness.

So, to understand the effective use of hard-facing welding electrodes, we need to understand what is wear & and learn more about the wear factors. Wear can be described as the process of constant loss of material or material integrity from a solid surface. Wear is a surface phenomenon and generally, causes of wear can be mechanical or chemical. The study of wear and related processes is also known as Tribology.

The factors of wear can be classified into two types –Primary wear factors & Secondary wear factors.

Primary Wear Factors-Abrasion, Friction & Impact

Secondary Wear Factors-Erosion, Corrosion, Heat, Cavitation

The seven factors listed above can all act on any component, causing the wearing out. There are various methods and solutions available to help combat these wear factors. However, let us first look at why we have classified them separately as primary and secondary wear factors.

The reason is really simple. The primary wear factors of Abrasion, Friction & Impact in general in all industry applications cause more loss of material or wear when compared to the secondary factors. Hence it is critically important to suggest solutions to combat the primary wear. Invariably, we find that some secondary wear factors also accelerate the wear. So, when we suggest solutions for any application, we need to study all the wear factors acting on the application and provide a comprehensive solution.

Typical Example: Let’s take the application of boiler nozzle tip in a power plant. Pulverized coal passes through the boiler tips in a power plant wearing down the component with high impact and abrasion. But, the wear is actually accelerated by the secondary wear factors of Heat, corrosion & Erosion as materials are carried by forced air when it is moving inside the boiler. So we need to select an LH Alloycapable of withstanding all these wear factors. Ador Fontech’sLH 743Nis a special constituent alloy that retains its hardness even at 650 degrees Celsius, making it the most suitable solution for this application, capable of dealing with the multiple wear factors.

One of the unique insights gained from studying the tribology of wear is that all applications in the industry will have a combination of wear factors. There is almost no application across the industry where we have only one wear factor. So when we offer a solution we need to understand the combination of wear factors acting on the component to provide a solution that ensures Life Enhancement.

This is the reason why we must understand the term hard facing. We must know that simple hardness in the application does not assure us of a component’s longer life. We get longer life with a correct LH Alloy which can tackle all the critical wear areas in the industry and offers the correct alloy combination & hardness. Let us see some industry examples to understand the concept of Wear facing using different Hardfacing alloys.

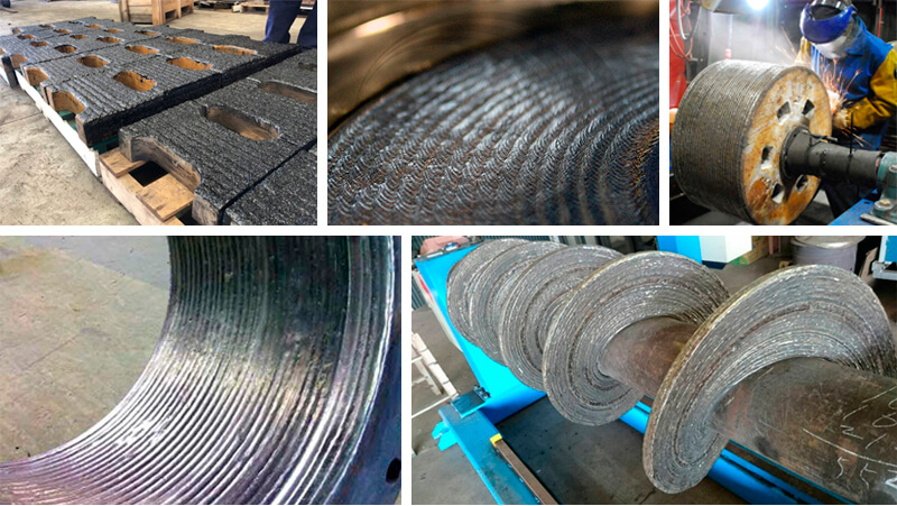

Typical applications you see in cement plant mines, steel plant mines, and in all mining area applications are repairing the hardfacing material of handling buckets in wheel loaders and porcelain machines. Typically, with the type of ore or material handled – limestone, iron ore, or coal, the normal wear factors in the application would be high abrasion caused by non-metallic particles on metal combined with impact. So it may be assumed that simple high Iron carbide deposits with 60 HRChardness should ensure a good life.

But in reality, we need to look at the application on-site and observe the terrain or conditions under which it is working. It may be working in the slushy and muddy conditions in high monsoon areas. It’s the type of customer who uses a lot of water to keep the environment friendly. Actually, we need a product with erosion and corrosion resistance. This means we need an Alloy that contains Chromium. Such subtle addition of alloying elements gives longer life. Even for this kind of application, Ador Fontech offers a solution with additional Chromium. For e.g., a product like LH 720 gives excellent Life Enhancement in comparison to conventional hardfacing electrodes with wear protection on secondary wear factors of corrosion and erosion Let us look at a second scenario.

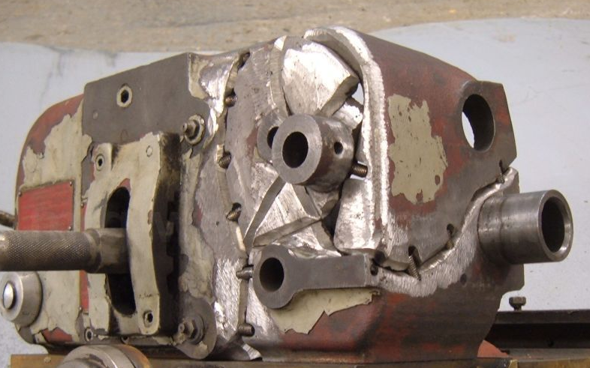

Crushers are used in mining to crush raw material. Depending on the type of industry, we have horizontal impact crusher equipment or hammer crushers with discs. These are widely used in this kind of application because the size of the particles and speed of crushing subject these components to very high impact combined with abrasion. To get the best results, it’s important to use a material with the correct microstructure to withstand the wear factors in such an application.

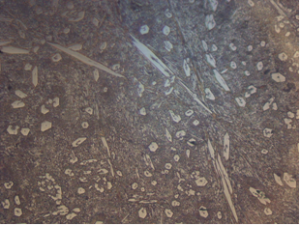

Normal Fe-Cr-C alloy system Special ADFL alloy system for impact application-

The above illustration shows two different carbide microstructures. The bigger carbide microstructure on the left fails as carbides are chipped off with high impact loading. The minutely, or evenly, distributed carbide on the right is best suited for a high impact & abrasion application and gives better life than the normal coarse carbide microstructure. The carbides are very difficult to dislodge because of the close fine carbide structure. At Ador Fontech, we have developed this special Alloy hardfacing electrode for high impact & abrasion application giving it the highest life enhancement with maximum productivity.

We hope the above salient points on tribology of wear and the three examples explain the problems with wear facing welding electrodes. Ador Fontech brings you a complete range of welding electrodes & Alloys to combat all wear factors. The most critical aspect of this range is that the solution comes in either welding electrode form or as open arc wires, to meet your application’s requirements.

Life enhancement of industrial components has formed the cornerstone of the services offered by Ador Fontech Limited, over the last 40 years and more. Partner with us to maintain and repair your equipment for tangible savings with minimum downtime and the highest productivity. Benefit the environment by conserving the non-renewable metal resources of the world.

Reclaim, Do Not Replace