Table of Contents

- Principle of Welding Processes

- Principle of Brazing and Soldering Process

- Welding / Shielded Metal Arc process (SMAW)

- Basic Requirements for Welding / SMAW process

- Welding Process Advantages

- Limitations of Welding Process

- Soldering & Brazing

- Four Requirements of Non-Fusion Welding

- Advantages of Non-Fusion –Brazing and Soldering Process

- Dis-advantages of Non-Fusion – Brazing and Soldering Process

To understand the basic difference between the three processes namely welding, brazing & soldering, we need to know about types of welding processes by principle.

Principle of Welding Processes:

- Fusion welding

- Welding done in liquid state without using pressure

- Union is by molten metal bridging of mating surfaces

Principle of Brazing and soldering Process:

- Solid phase welding

- Welding done below the melting point without any filler additions

- Pressure is often used in this type of welding

- Union often occurs when material is in plastic flow

The Welding process is a Fusion process where as brazing and soldering are both solid phase welding processes.

Let us understand more about these three processes, which are widely used by many industries.

Welding / Shielded Metal Arc process (SMAW):

Shielded Metal Arc process is also known as manual metal arc welding process. In this process, an arc gets established between parent metal and a flux coated welding electrode using electrical energy. This arc melts the deposit weld metal and nn this process, actual melting of base metal and welding electrode bridges the gap and forms the welding This process is one of the most used welding processes in the world.

Basic Requirements for Welding / SMAW process:

Heat source – Welding Equipment Current Range 30-400 A –depending on size of electrode in general, even though welding machines that use up to 600 Amps AC as well as DC welding machines are equally useful in a SMAW Operation.

Welding Consumable: Flux coated welding electrodes (1.6- 8 mm diameter) are needed for the process along with a welder who is trained to manage the welding.

SMAW or MMAW is a commonly used welding process in the world.

Welding Process advantages:

- Simplest of all welding processes

- The equipment used is portable

- Cost of equipment is economic

- It has a variety of applications

- There’s wide availability of electrodes

- Can weld a wide range of metals & their alloys

- Welding can be done from any position

- Welding can be done indoors & outdoors

- Welding cable extension goes very far

Limitations of welding process:

- Low productivity as in a 10-minute cycle, welding happens only for 6 minutes

- Process also involves frequent change of welding electrode

- Moisture from flux coatings can create weld-related problems

- Safety issues with arc strike, shocks from stray current/electric power

- Process is completely manual as the name ‘Manual metal arc welding’ suggests

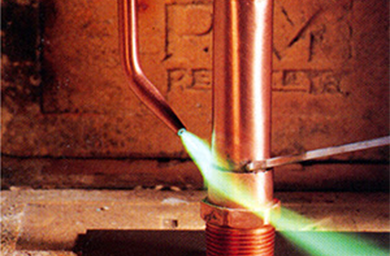

Soldering & Brazing:

In both the above processes joining happens by diffusion welding methodology, The joining happens through atomic diffusion of two surfaces in contact. Surfaces are usually heated to high temperature (below their melting point) & pressure may also be employed.

- Soldering: Soldering as a process happens below 450 degrees Celsius Normally lead or tin based alloys are used for soldering

- Brazing: This process happens between 450 degrees and 750 Degrees Celsius Silver & copper-based alloys are used for brazing.

Four Requirements of Non-Fusion Welding

- Clean Surface: Non-fusion processes bond metal by adhesion, where adhesion happens to be the molecular attraction between bodies in contact.

- Molecular bonding requires a clean surface.

- Filler Rod:

- Filler rods are used in many non-fusion processes.

- Brazing:

- Brazing rods can be bare rods or flux coated.

Soldering:

- Solder can be solid or flux core/paste

- Can be tin, silver or zinc alloy

- Promotes wetting

- Flux :

Flux has applications in all non-fusion welding processes.

Purpose of flux:

- Chemically cleans the metal

- Shields weld from oxidation and atmospheric contamination

- Heat Source

The heat must be sufficient (BTU”s) to raise the base metal temperature above the melting point of the filler rod.

To achieve this, several heat sources can be used.

- Oxyacetylene

- Air acetylene

- Air propane (LPG)

- Oxypropane

- Electric soldering iron

- Electric soldering gun

Advantages of Non-Fusion –Brazing and Soldering Process:

- Lower temperature process

- Easy assembly of parts

- Welding dissimilar metals

- Allows disassembly/realignment

- Joins metals of different thicknesses

- Joint different types of metal

Dis-advantages of Non-Fusion – Brazing and Soldering Process:

- Lower tensile strength

- Not an efficient method for thick metal

- Not an efficient method for large parts.

So, the essential difference between Welding, Soldering & Brazing is as below.

- Welding is a fusion process, where there is a homogenous bonding of joining surfaces.

- While brazing and soldering are basically non-fusion processes which use diffusion to join materials.

All three processes have a wide variety of applications in industries depending on the uses and requirements. ADFL serves the industry with manufacture and supply of products in all three processes.

Repair – Do not replace