Table of Contents

- MMAW / Arc Welding Equipment – Features

- MMAW / Arc Welding Equipment – Advantages

- Types of Arc Welding Equipment / Power Sources

- Motor Generator

- Welding Rectifier

- Welding Inverter

In fabrication, welding helps to join materials using heat to melt the parts together. Useful with metals and thermoplastics, this process typically uses a filler material to the weld pool of molten material, helping to make the joint stronger than the base material. Pressure is used in the process along with heat in welding, while a shield protects the metals from being oxidized in the process.

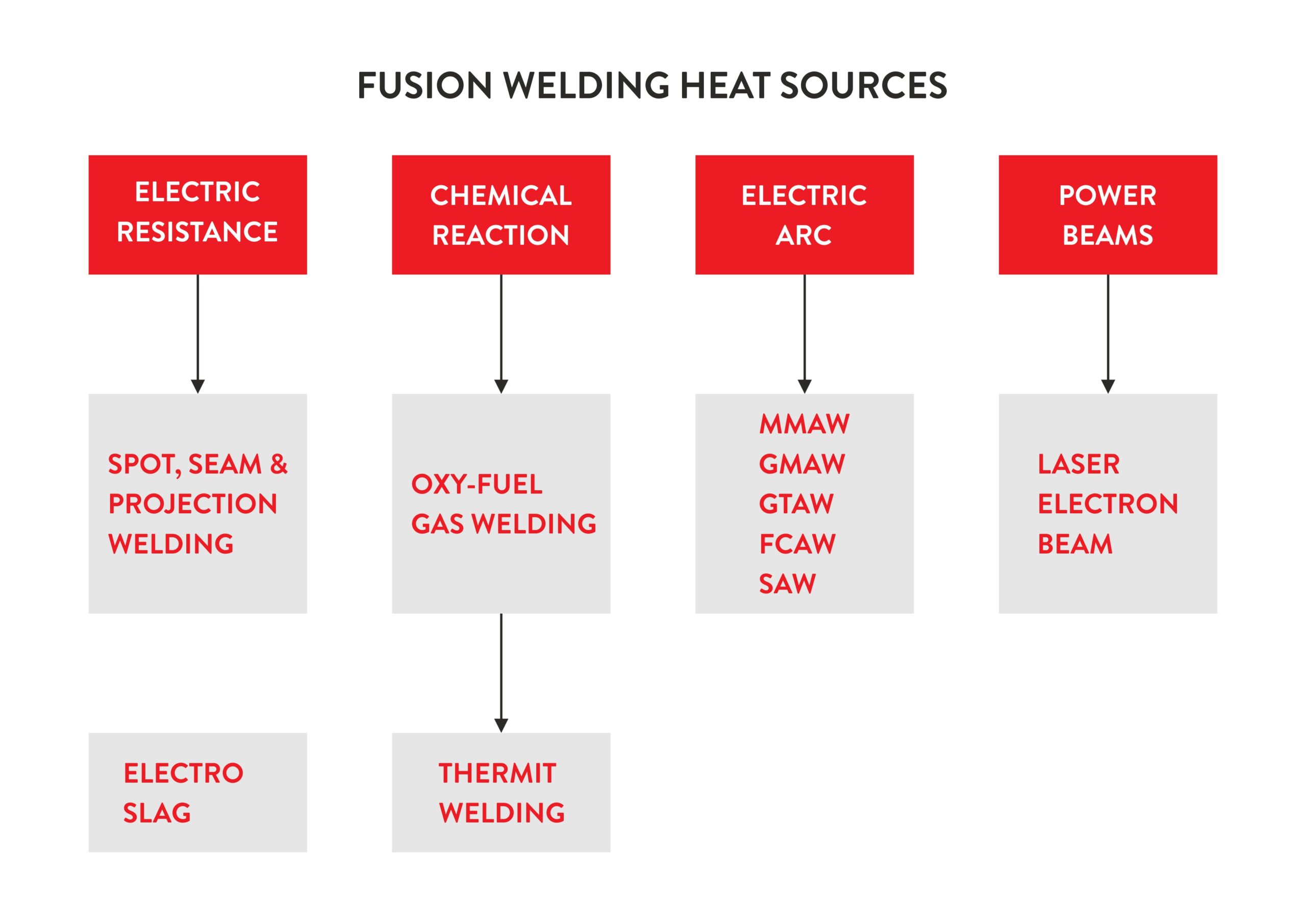

The most heat sources for joining material using a fusion welding process are listed below:

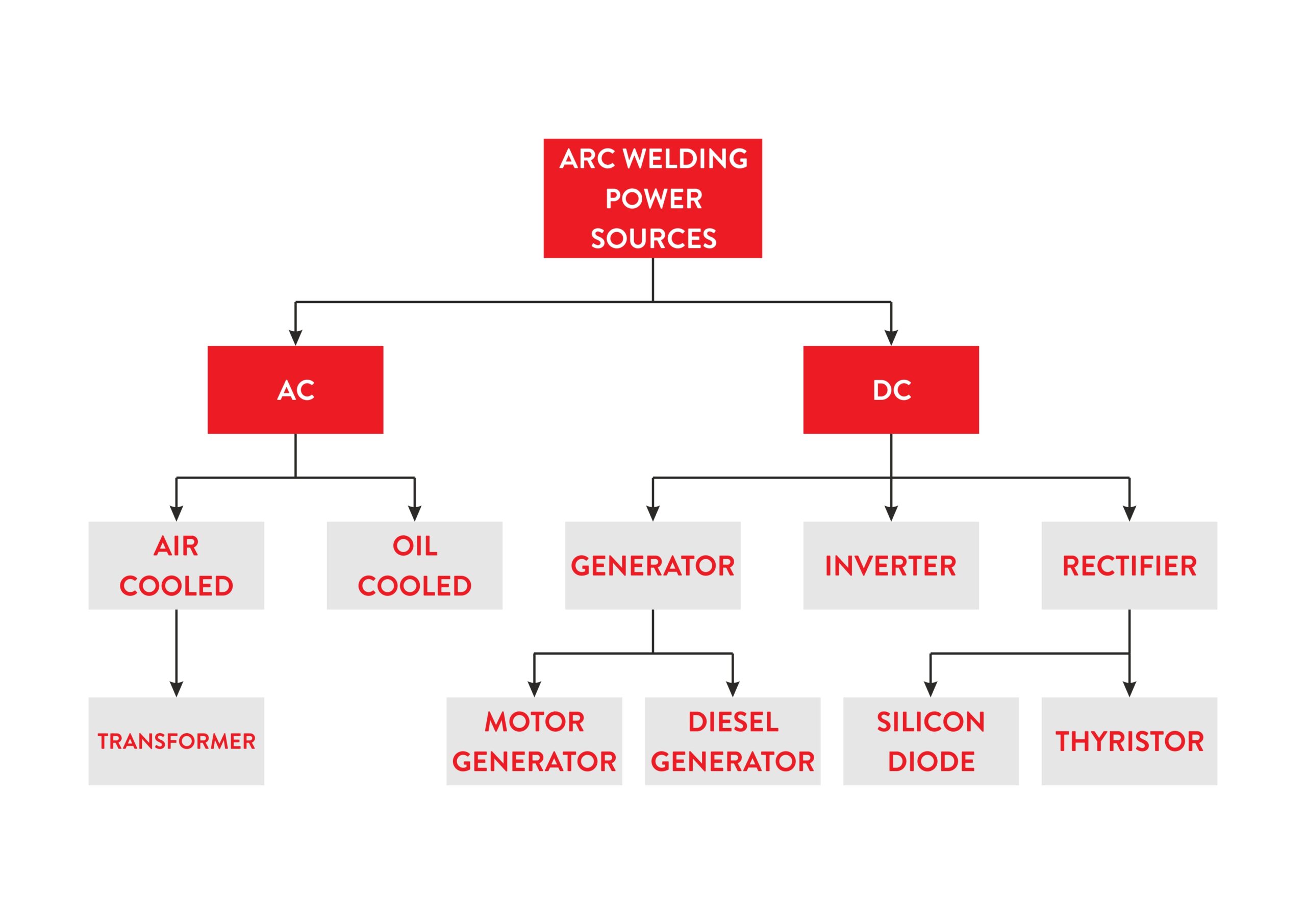

We have five types of Arc welding Equipment/power sources. These are AC transformer; DC rectifier; AC/DC transformer rectifier, DC generator, and inverter.

MMAW / Arc Welding Equipment – Features

- Portable & Versatile equipment

- Requires practiced skills

- Applicable to a wide range of materials, joints, positions

- About 1kg per hour of weld deposited

- Properties can be excellent

- Benchmark process

MMAW / Arc Welding Equipment – Advantages

- This is the simplest of all Arc welding processes.

- Equipment is portable

- Economical Cost of Equipment

- Variety of applications & wide availability of electrodes

- The range of metals & their alloys can be welded

- Welding in all Positions

- Welding can be Indoors or Outdoors

- Welding cable can be extended to long distances when compared to other processes

Types of Arc Welding Equipment / Power Sources:

A welding transformer is basically a step-down transformer that brings down the source voltage to weldable voltage. This is simple Arc welding Equipment.

Motor Generator

Motor Generator is also an Arc welding Equipment, which utilizes input power to rotate the generator through an induction motor. This kinetic energy is converted to electrical energy by carbon brushes fitted in the commuter, generating DC current is generated supplying constant power to the process.

In a Diesel Generator, diesel is used as fuel to run the motor to generate electricity; this is widely used in on-site jobs for Arc welding applications

Welding Rectifier

Welding rectifiers are essentially transformers with an electrical device as a rectifier which changes AC to DC. Rectifier basically consists of Silicon diodes, which ensure the flow of current in one direction giving DC output. This is most commonly used with Arc welding equipment.

Welding Inverter

This latest technology power source is the most popular Arc Welding equipment today. A welding inverter is a power block, controlled by software, which offers the required static and dynamic characteristics needed for a specific welding process. It takes AC input and converts it into DC after step-down & then converts it further into high-frequency AC & then again converts it to DC – finally offering a DC output. When using an inverter power source, a user gains all the advantages of thyristor control. Additionally, they get superior efficiency, power savings, better performance, and quality of welding.

We at Ador Fontech offer the best “Make in India” solutions with Fontech Tornado brand Welding Power sources. We offer both robust Thyristor-controlled machines as well as Power saving Inverter machines for all welding processes like Manual Metal Arc welding, TIG, MIG/MAG, and SAW. Once again, we reiterate our total commitment to total solutions in welding with this range of equipment, catering to the complete requirements of customers.

Reclaim. Do not Replace.

Also read:- Hypertherm Life Expectancy of Consumables