When it comes to cutting metal, two widely used thermal processes are oxyfuel and air plasma. Although oxyfuel is proven, plasma is more versatile—and less expensive—with a better performance record.

Versatility

Oxyfuel can only cut ferrous metal. It cannot cut non-ferrous material, stainless steel, or aluminum, and is generally only used to cut metal approximately 2 inches (50mm) in thickness or greater. Plasma can cut both ferrous and non-ferrous material including rusted, painted, or grated metal.It is most commonly used to cut metal between gauge and 2 inch thick material.

Safety

When it comes to safety, oxyfuel is at a disadvantage because it requires a highly flammable fuel gas and an open flame. Once the torch is lit, the flame stays on until the system is manually turned off. Plasma does not use a fuel gas and its arc automatically extinguishes when the torch is removed from the metal.

Ease-of-Use

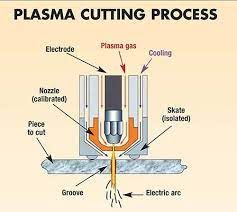

Ease-of-use minimizes training, improves results, and increases profitability. When comparing oxyfuel to plasma, the latter prevails as air plasma uses compressed air. There are no gases to mix or regulate. With oxyfuel, operators need to set and maintain the flame chemistry while holding a steady distance between the tip and surface being cut. Many handheld plasma torches allow the operator to drag the torch on the material. No standoff is needed.

Cut Quality

Manufacturers now have to compete on product quality more than ever. Overall, plasma produces more precise and cleaner cuts than oxyfuel with better angularity, a thinner kerf, a smaller heat affected zone, and zero to no dross.

Productivity

At a minimum, plasma is twice as fast as oxyfuel when cutting metals up to 25mm in thickness and up to 12 times faster on thinner materials. Productivity is also affected by piercing delays. It can take 30 seconds to pierce 16 mm thick steel with oxyfuel. Plasma takes less than two seconds.

Operating Cost

There are generally three things that affect the operating cost of oxyfuel and plasma: consumables, power, and gas. Generally, consumable and power costs are higher for plasma and gas costs higher for oxyfuel. While the operating cost of oxyfuel is seemingly lower, it is not the most economical to operate because of plasma’s productivity advantage.

In conclusion, oxyfuel and plasma are both well-established thermal processes for cutting metal. In deciding which method to use, companies need to weigh the above factors against individual business needs. For more on cutting metal, contact Hypertherm (www.hypertherm.com) a manufacturer of cutting systems with a nearly 50 year history of helping businesses succeed.

Source: https://www.hypertherm.com/

Gas Cutting or Oxy-fuel cutting Advantages

Gas Cutting or Oxy-fuel cutting Advantages Easy to use

Easy to use