Key Differences Between SMAW and SAW Welding

Table of Contents

- An Introduction to Shielded Metal Arc Welding (SMAW) process

- Heat source

- Energy Consumption

- An Introduction to Submerged Arc Welding (SAW) process

- Advantages with the SMAW Process

- Limitations of the SMAW process

- Advantages with the SAW Process

- Limitations of the SAW process

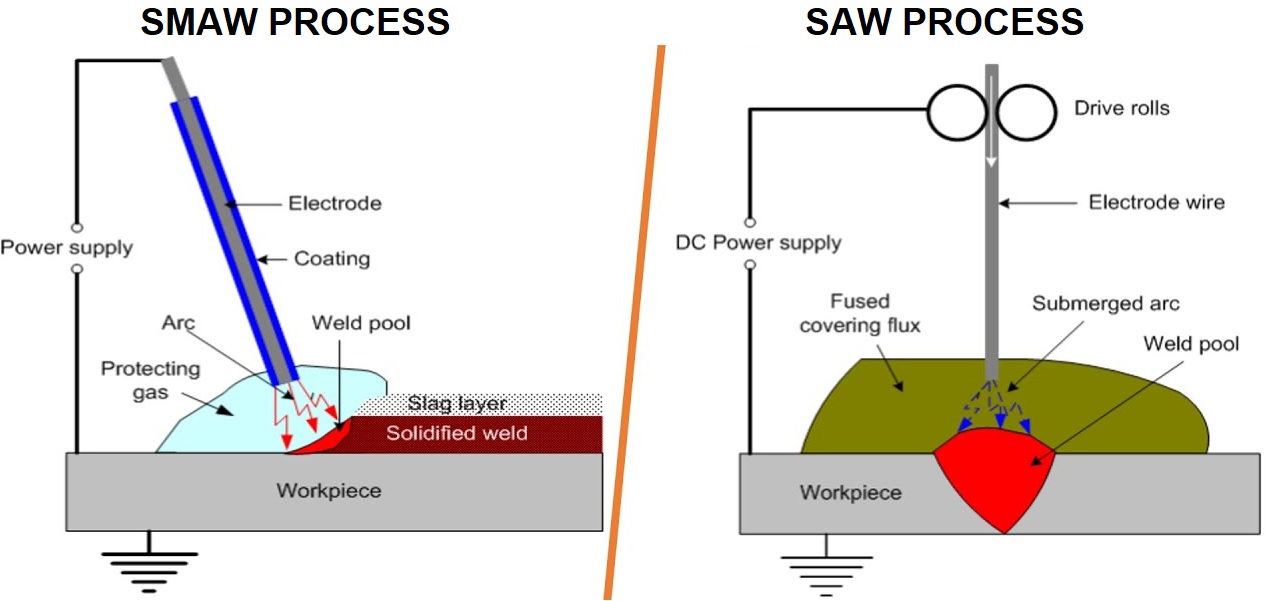

The basic difference between the two processes, SMAW and SAW welding, is this. In the SMAW process, the flux-coated electrode helps to shield the welding process from any interaction with the atmosphere. In the SAW process, an external flux delivered at the arcing area acts as a shield. So, the welding happens underneath the powder flux fed by a delivery system. This is the primary difference between SAW & SMAW processes. Let us get introduced to both processes.

An Introduction to Shielded Metal Arc Welding (SMAW) process

In SMAW or MMAW (Manual Metal Arc Welding), the arc is established between Parent Metal shielded (flux-coated) welding electrodes using electrical energy to deposit weld metal.

Heat source: Arc between metal and a flux-coated electrode (1.6- 8 mm diameter)

Energy Consumption: 30 – 400 Amps –depending on the size of the electrode in general, even though there are welding machines that use up to 600 Amps. AC or DC SMAW Operation Power consumption 1-12 KW

An Introduction to Submerged Arc Welding (SAW) process

In the SAW Process, as the name signifies, the welding happens submerged beneath the flux. SAW process also employs a welding consumable, usually a wire. An arc is established between the welding wire and base metal and welding happens underneath the metal powder of flux, which shields the arc from the atmosphere.

Heat source: Arc between a wire and base metal

Current Range: 200 Amps -1200 Amps

DC operation

Power Consumption-35-56 KVA

- Power source

- Welding head and control box

- Welding head travel

- Flux recovery system (optional)

Let us take a look at the process advantages & limitations of both SMAW and SAW processes.

Advantages with the SMAW Process:

- This is the simplest of all Arc welding processes.

- Equipment is portable

- Cost of equipment is economical

- Variety of applications & wide range of electrodes available

- A range of metals & their alloys can be welded

- Welding can be done in all positions

- Welding can happen indoors & outdoors

- Welding cable can be extended to long distances in comparison to the SAW process

Limitations of the SMAW process:

- Low productivity as in a 10-minute span, welding happens only for 6 minutes

- The process also involves the frequent change of welding electrode

- Moisture from flux coatings can create weld-related problems

- Safety problems like arc strike, stray current & electric shock risks

- Absolutely manual process – hence called Manual Metal Arc Welding

Advantages with the SAW Process:

- High productivity up to 2 to 10 kg per hour.

- Speed almost up to 2m/min

- Can be easily automated for even higher productivity.

Limitations of the SAW process:

- Bulky, expensive, and heavy equipment

- Flat and horizontal positions only

- Thicker sections (6mm and above)

- Mostly ferrous materials (also Ni alloys)

Given these essential differences between MMAW/SMAW and SAW processes and their respective advantages and limitations, a considered choice can be made between these processes.

We, at Ador Fontech, offer the best “Make in India” solutions with Fontech Tornado brand welding machines for both SMAW and SAW processes. Once again, we reiterate our commitment to total solutions in welding to the complete satisfaction of customers, with this range of equipment.

Also read:- Resolve Wear Factors